It’s the little things that count. Whatever your hobby, passion or obsession, when taking a measurement, it generally isn’t the actual measurement that influences the quality of what you are constructing; it is the tolerances you are working to.

When knocking up the frame for a kid’s cubby house for example, having a measurement out by 5mm or more is not the end of the world, and the measuring tools you use reflect this. A tape measure is certainly accurate enough for this work. But if you are making a fine wooden box, for a measurement to be out by 5mm (or even 1mm) is disastrous, and is the difference between a beautiful heirloom-quality keepsake, and one made by a 10-year-old in a woodshop class at school.

Your medium of choice does play a large factor: in metalworking, tolerances of +/- 0.001mm are not uncommon. In woodworking, +/-0.1mm is working accurately, and in carpentry +/-1mm is fine. After all, timber is rather forgiving – it compresses, there are fillers (and filling techniques), glue can span small gaps and nails can span large ones!

Like so many other areas of life, there is a digital revolution underway, and when it comes to taking measurements, accuracy is certainly the winner. The digital tools now available (at an affordable price) provide an incredible convenience so that there is no real excuse to avoid accuracy.

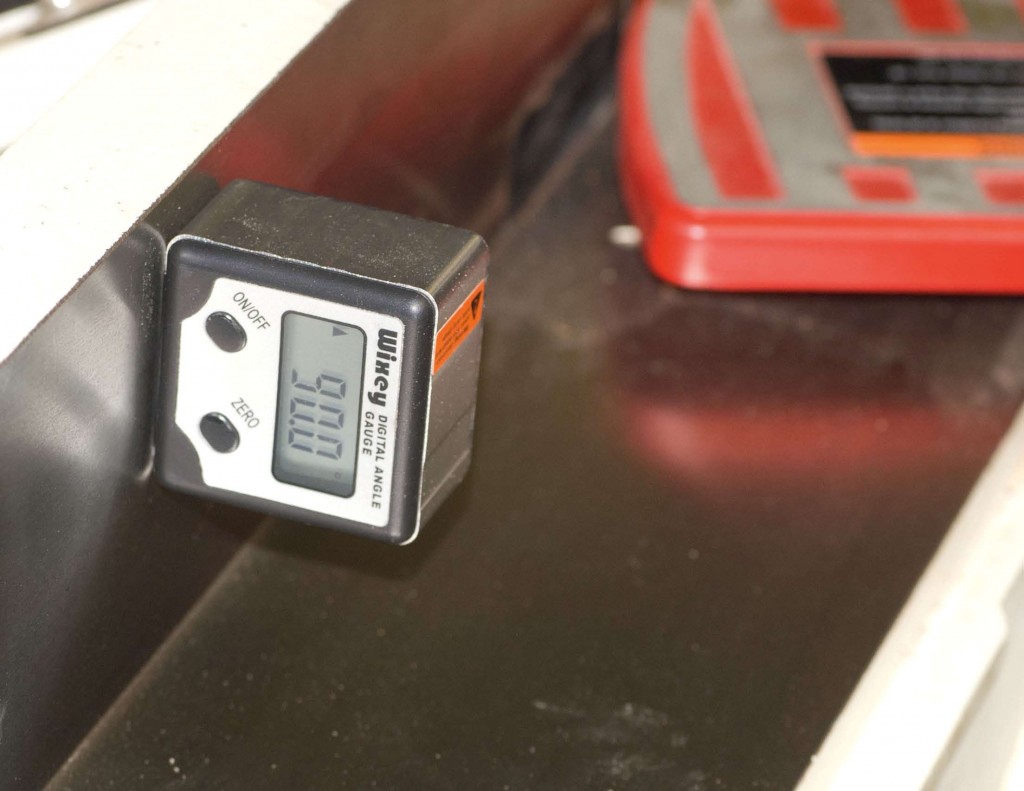

Angle gauge

This is one of those tools I call a ‘shop apron’ tool: one that is so useful, it should always be on hand (such as in the pocket of your shop apron).

No longer relying on the rule or measure on the tool itself (where you’d often be lucky to get within a degree or five), or using a square for a basic setup, with a digital angle gauge you can set extremely accurate angles, within +/-0.05 degrees. The gauge gets zeroed off one surface, then compared to the second.

For example, when setting up a planer, zero off the base, then set the fence to the desired angle.

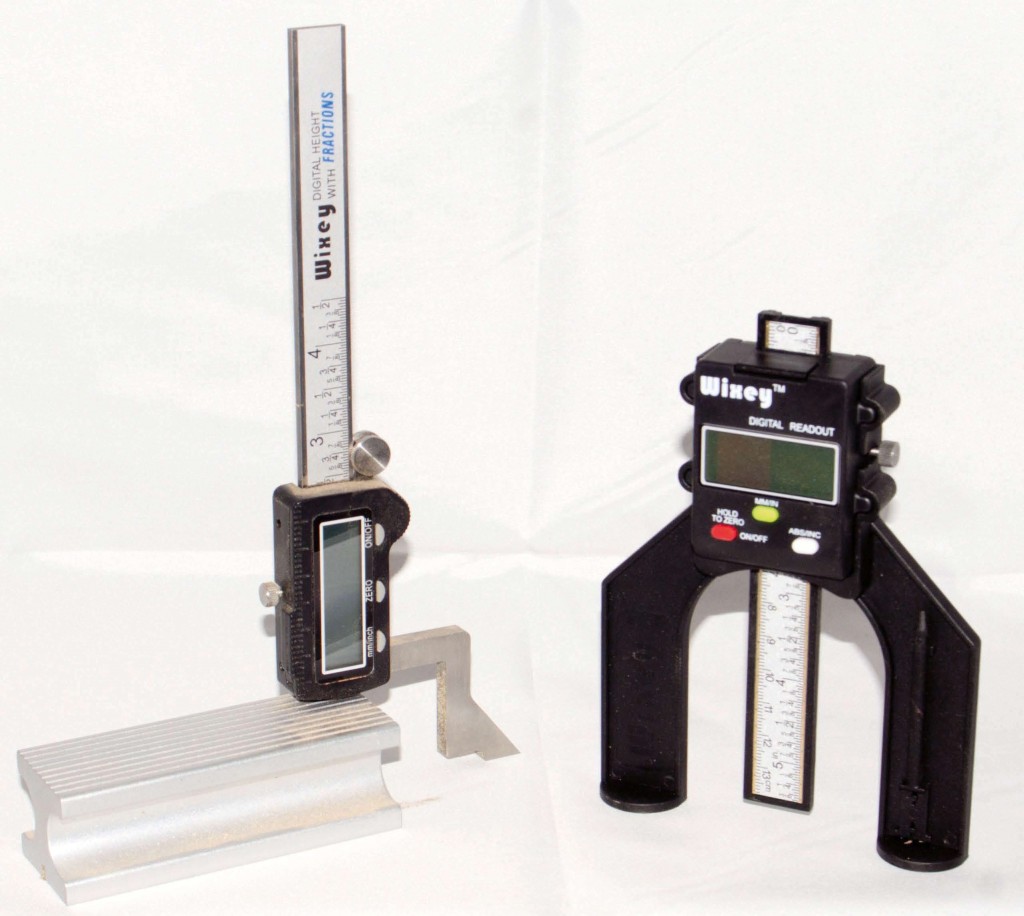

Height gauge

The height gauge is especially useful for precise, repeatable setup, where cutter height is critical. The cutter can refer to a blade (such as a circular saw blade), a rotating cutter (router bit or high speed rotary), plunge cutter (such as a drill bit) – pretty much any situation where a cutter protrudes from a reference plane.

It can also be used to set fence to cutter distance.

With accuracy to +/-0.05mm, the old steel rule and ‘eyechrometer’ is in danger of becoming a thing of the past.

Tool-mounted linear gauge

The digital revolution is not restricted to handheld rules and gauges, and the various workshop tools can also significantly benefit from a digital upgrade.

They are particularly beneficial on machines that have a cutter above a reference surface (such as a thicknesser or drum sander), but can also be applied to many other situations where the cutter height is changed in a linear direction between passes.

This will completely revolutionise how you use these tools. Instead of running a pass through the thicknesser for example, then using a digital caliper to see how thick the timber is, then deciding how many quarter turns of the handle to go, you can get the height close (safely), then run a final light pass to nail the thickness you want, accurately and easily.

Where it is impractical to have the readout at the point of measurement, it can be transmitted to a conveniently located readout, such as on a router table, where the position sensor is mounted to the router, and the readout to the router table fence.

The table saw fence runs horizontally over a much larger range than tools that operate vertically need to deal with, and again, there is a digital gauge available.

The concept is clever in its simplicity – a digital readout (that attaches magnetically to the fence) that runs up and down an auxiliary track. This has a conductive strip attached so the readout can determine its position (or more precisely, change in position). It is accurate to 0.1mm, which is pretty impressive for a table saw fence.

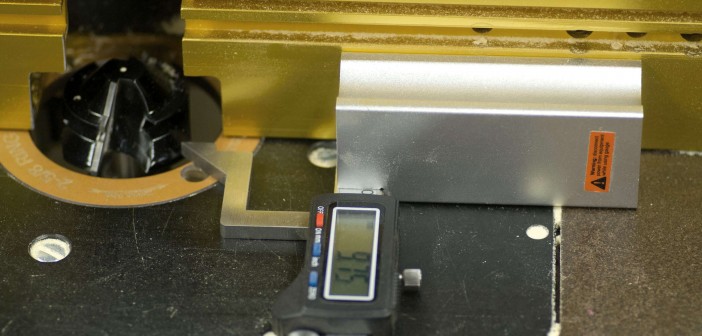

Digital caliper

The digital caliper has become quite a standard tool these days, again providing ease of use, incredible accuracy, measuring internal distance and external distance (typically timber thickness) and depth of grooves, rabbets, holes etc.

Whether it is used to determine the exact diameter of a hole, or the thickness of a hand-planed shaving, the digital caliper is invaluable.

These are just some of the new gauges and measures now available to digitise your workshop. They are accurate and affordable and can help you take your next project to a higher level of quality than you dreamed possible.

Smart phones

Finally, don’t forget the humble iPhone. There are many apps now available for shed dwellers (woodworkers, metalworkers, just to name a few). Everything from plumb bobs through to angle gauges.

So have a look at the various machines and practices in your workshop – there is likely to be a way to add a digital gauge, or use a handheld version to take your next project to another level. (Couldn’t help the pun!)

All gauges and tool upgrades seen in this article are made by Wixey in the USA, and available from Professional Woodworkers Supplies (www.woodworksupplies.com.au), excluding the iPhone app, from the iTunes store.